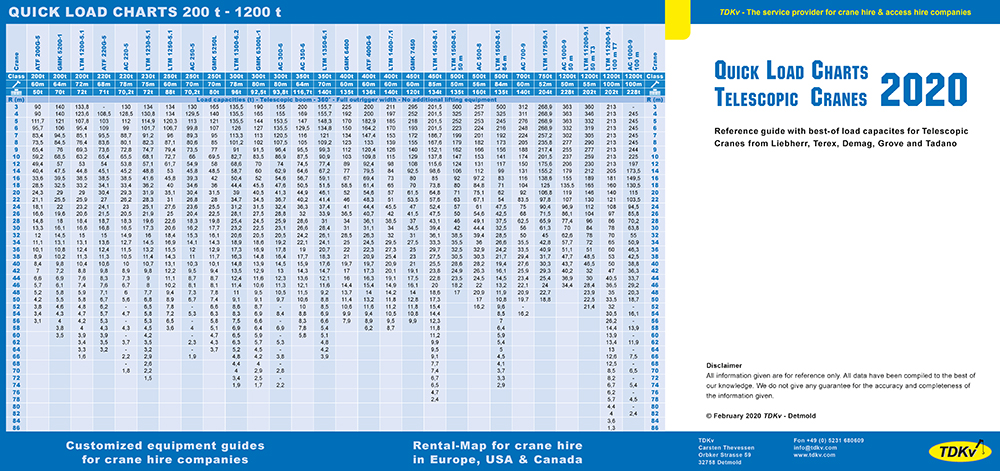

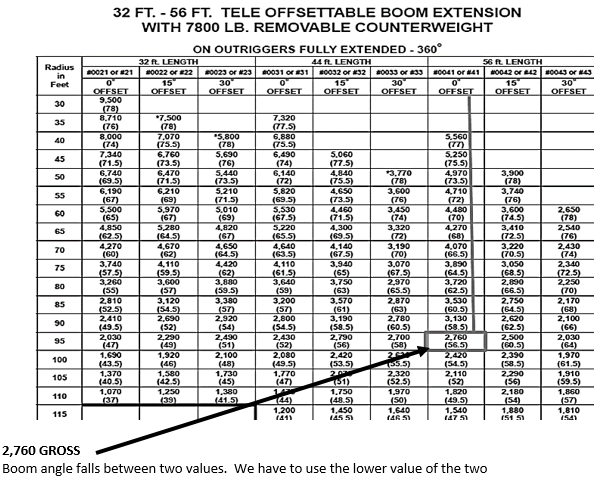

This chart is designed specifically for cranes and will let you know how much it can lift depending on its position, extension, and base. What Is a Crane Load Chart?Ī crane load chart is a simple document that highlights the lifting capabilities of a particular crane. Here’s a quick look at how to read a crane load chart.

Understanding how to read one will not just keep your warehouse efficient, it will also keep everyone safe. Whether you have an outdoor construction crane or an indoor warehouse crane, it’s important to know how to read a crane load chart. This is because they are incredibly efficient and reliable for repetitive operations. On the other hand, indoor cranes like overhead cranes and bridge cranes are ideal for warehouses and loading yards.

This means that you can quickly assemble it on a construction site, or move the crane from one location to another. Outdoor cranes tend to be more mobile and flexible. Some cranes are used outdoors for construction while others are used indoors for logistics.Įach kind of crane comes with its own pros and cons. The best way to distinguish the various cranes is by looking closely at their uses. Currently, we have a wide variety of cranes that can help with numerous different tasks. While ancient trains may have looked and operated completely differently, they still relied on the same core principles of leverage. Different Kinds of CranesĬranes have been around for thousands of years. Here’s what you need to know about reading crane load charts. Interested in learning more about load charts for cranes? You’re in the right place. This will ensure that you maximize productivity while remaining safe and efficient. While these machines are great for lifting and moving heavy items around, it’s essential that your staff understands how to read crane load charts. This refreshes everyone’s skills and can help improve productivity at the ground level.Ĭranes and forklifts are some of the most popular warehouse equipment options within the logistics industry.

However, offering safety and equipment training to your staff is just as essential. Many people assume that warehouse maintenance is solely about repairing physical equipment. It’s essential that operational training form part of your warehouse maintenance every year.

0 kommentar(er)

0 kommentar(er)